- What is palladium?

- Role of Palladium in Catalytic Converters

- How many grams of palladium in a catalytic converter?

- Factors Affecting Palladium Content

- Impact of palladium Price Changes on Converter Price

- How to remove palladium from a catalytic converter?

- Which catalytic converters have the most palladium?

- How to Recycle My Catalytic Converter?

Catalytic converters, pivotal in reducing vehicle emissions, house a trio of precious metals such as platinum, palladium, and rhodium. These elements catalyze chemical reactions that transform harmful pollutants into benign gases. Among these, palladium plays a crucial role, in balancing efficiency and cost-effectiveness. Today, our focus hones in on palladium's value within catalytic converters, unraveling its quantity and impact in mitigating environmental harm. We are also going to explain the element, its role in converters, how expensive it is, how to retrieve it by recycling the used catalytic converters, and the benefits of doing that.

What is palladium?

Palladium, a lustrous silvery-white transition metal, resides in the platinum group on the periodic table, alongside platinum, ruthenium, rhodium, iridium, and osmium. Its atomic number 46 and chemical symbol Pd denote a remarkable element prized for its exceptional catalytic properties and remarkable resistance to corrosion. This metal, though relatively abundant compared to some others in its group, remains rare in nature, typically found in ores alongside nickel, copper, and platinum deposits. Mining efforts, largely concentrated in regions like Russia, South Africa, and North America, involve extensive extraction processes, including both traditional mining methods and recycling due to the burgeoning demand for palladium in various industries, notably automotive, electronics, and jewelry. Beyond its industrial utility, palladium exhibits a unique ability to absorb hydrogen at room temperature, making it invaluable in hydrogen storage and purification technologies.

Role of Palladium in Catalytic Converters

Palladium is one of three general catalysts of catalytic converters. Catalysts are meant to accelerate chemical reactions without undergoing any permanent change. When integrated into the converter's structure, palladium facilitates the conversion of harmful gases like carbon monoxide, nitrogen oxides, and hydrocarbons into less harmful substances by promoting oxidation and reduction reactions. Its unique surface characteristics enable the breaking down of toxic compounds into less detrimental emissions, aligning with environmental regulations. The use of palladium in catalytic converters exemplifies its unmatched efficacy in mitigating vehicular pollution, making it an indispensable component in modern automotive emission control systems.

How many grams of palladium in a catalytic converter?

The quantity of palladium in a catalytic converter varies depending on the converter's type, vehicle make, and model year. Generally, modern converters contain between 3 to 7 grams of palladium, but this can fluctuate based on design advancements and emission standards. High-performance or larger vehicles might house converters with a higher palladium content to manage increased emissions. Conversely, smaller or older models might contain less palladium. The evolving landscape of emission regulations and technological innovations also influences the palladium quantity, with newer converters often employing smaller amounts due to more efficient designs or alternative catalyst materials.

Factors Affecting Palladium Content

Several additional factors influence how many ounces of palladium in a catalytic converter:

- Euro Emission Standards: Stricter regulations demand converters with higher efficiency, potentially increasing palladium usage.

- Converter Types: Three-way converters, handling multiple pollutants, often require more palladium due to their comprehensive function. Diesel oxidation catalysts, targeting specific emissions, might contain comparatively less palladium.

- Ceramic Honeycomb Structures: Advanced designs enhance the surface area, allowing for reduced palladium usage without compromising efficiency.

- Technological Advancements: Integration of alternative catalyst materials impacts palladium quantities, influencing converter designs.

The interplay of regulatory standards, technological evolution, and engineering strategies determines palladium content, showcasing the complex dynamics shaping catalytic converter compositions.

Impact of palladium Price Changes on Converter Price

Fluctuations in palladium prices exert a significant influence on the costs of catalytic converters, raising the perennial query: "How much palladium is in a catalytic converter worth?" The price of palladium, determined by the precious metals exchange markets, experiences notable volatility due to its demand across diverse industries. Industries such as automotive, electronics, and jewelry heavily rely on palladium, creating interconnected dependencies that result in correlated price fluctuations.

The automotive sector, being the primary consumer of palladium for catalytic converters, witnesses substantial impacts. Price variations in palladium directly influence the manufacturing expenses of converters, which, in turn, affect the overall vehicle production costs. This cost sensitivity trickles down to consumers, potentially influencing vehicle prices and the parts in response to palladium price shifts.

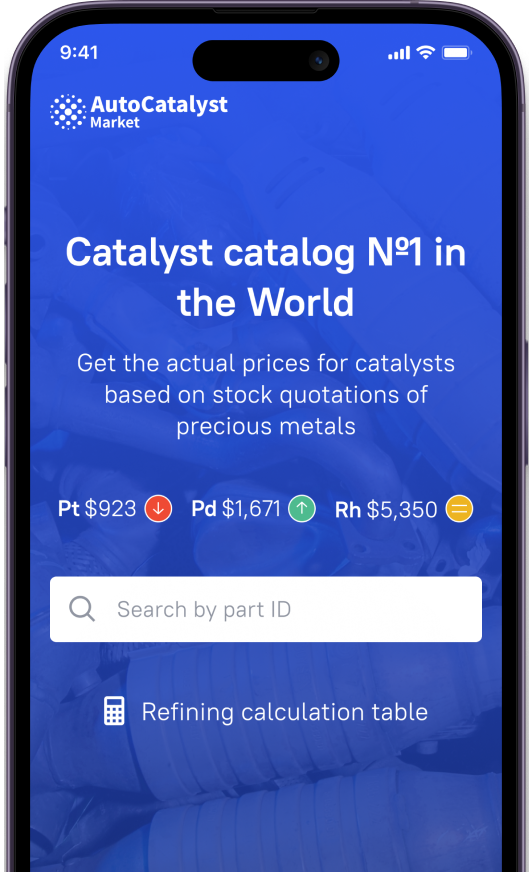

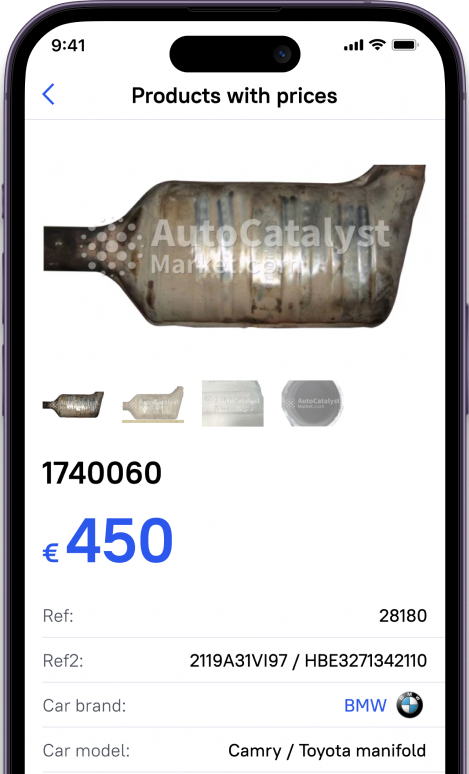

Navigating these fluctuations requires a comprehensive understanding of the market. The AutoCatalystMarket website serves as an indispensable tool, offering an extensive database comprising 25,000 units of catalytic converters, complete with images for easy identification. It is a vital resource for price estimations, tracking the dynamics influenced by the intricate interplay of factors affecting catalytic converter costs. Here you can always get the actual price for a specific catalytic converter.

How to remove palladium from a catalytic converter?

Extracting palladium from catalytic converters primarily occurs through recycling processes. This involves several stages:

- Decanning: Removing the catalyst from the converter's shell.

- Decomposition: Heat treatment to eliminate organic materials.

- Chemical Treatment: Dissolving the metals using strong acids.

- Precipitation: Adding specific agents to separate palladium from other metals.

- Refinement: Further purification to obtain high-purity palladium.

Recycling not only recovers palladium but also reduces environmental impact and conserves natural resources. It's a sustainable practice crucial for managing the global demand for precious metals. Thus, while extracting palladium from converters is intricate, recycling ensures its reuse while minimizing its ecological footprint. Moreover, you save on purchasing a new catalytic converter via recycling after the device failure.

Which catalytic converters have the most palladium?

Certain catalytic converters, like those found in high-performance vehicles or larger models, often contain more palladium due to their increased capacity to manage emissions. For instance, premium car brands like BMW, Mercedes-Benz, or Audi commonly equip their models with advanced emission control systems utilizing catalytic converters with higher palladium content. Additionally, heavy-duty vehicles such as trucks or SUVs may incorporate converters with elevated palladium levels to address larger emission outputs.

Determining the precise palladium or other precious metal content in specific converters requires recycling processes. Only through methods like XRF (X-ray fluorescence) analysis conducted on samples extracted from the converters can the quantities of metals like palladium be accurately established from the whole scrap weight. This underscores the significance of recycling in not only reclaiming palladium but also in comprehensively assessing and recovering other valuable metals present in these catalysts for future applications in various crafts.

How to Recycle My Catalytic Converter?

Selling a used catalytic converter presents two primary pathways. Traditional scrapyards, although easily accessible, carry inherent downsides. While proximity proves advantageous, these yards often engage in illicit activities involving stolen catalysts and frequently undervalue purchases.

On the contrary, online platforms like AutoCatalystMarket offer a more advantageous choice. This method links sellers with trustworthy buyers, ensuring fair dealings and bypassing the risks associated with scrapyards. Regional dealer options ensure tailored accessibility to suit individual sales requirements.

To sell via AutoCatalystMarket, follow these steps:

- Prepare Your Catalyst: Ensure it's ready by removing excess components for shipping.

- Get Quotes: Interact with potential buyers for accurate pricing or local initial quotes.

- Optional Shipment: Pack securely for shipping if preferred.

- Secure Payment: Expect swift payment upon buyer confirmation.

Utilize AutoCatalystMarket's efficiency to streamline used catalytic converters' recycling and sales processes. Manage these steps effortlessly from your smartphone's comfort, all at your fingertips. This user-friendly platform empowers easy communication with potential buyers, obtaining quotes, and finalizing transactions hassle-free.

Experience the ease of recycling through AutoCatalystMarket, enhancing your catalyst selling journey effortlessly and efficiently.